When we inspect a dust collection system, we always work on the PD blower (positive displacement blower) if equipped with one.

|

| Figure 1 a PD blower with intake filter taken out |

Intake filter

Nearly every time an intake filter was taken out, it was dirty and covered with dust or dirt. Since the intake filter is normally shrouded inside of a cover, it is not visible and is forgotten or ignored easily by maintenance guys or other service contractors.

If it is a paper or felt element, we will tell the customer when to replace it, or if it is a wire mesh element, we will clean it with lukewarm water, and if there is oil on it, we will wash it with mild detergent.

Because of the tight clearances used in the design and manufacturing of the PD blowers, they require filtered intake air. Proper maintenance of the intake filter will help insure a long service life for the PD blower.

Consequently, a clogged intake filter will cause poor performance and overheating of the PD blower.

Here is an example of a clogged intake filter (Figure 1, 2&3), taken out and cleaned in one of our on-site works.

|

| Figure 2 The intake filter of the PD blower above was taken out for cleaning |

|

| Figure 3 the clogged intake filter for the PD blower above |

The intake or inline filter should be cleaned every 40 hours or more often if dust conditions are severe, or every time you check the drive belts for tension, and at least once between two consecutive checks.

From our experience, a paper or felt element is strongly not recommended. They are so easy to get completely blinded, especially when running on a rainy day. A PD blower is not designed to run at zero airflow.

Silencers

Secondly, silencers are easy to forget and get ignored as well, and they also should be inspected periodically for being plugged, corrosion, oil coating and for any deterioration.

Pressure relief valve

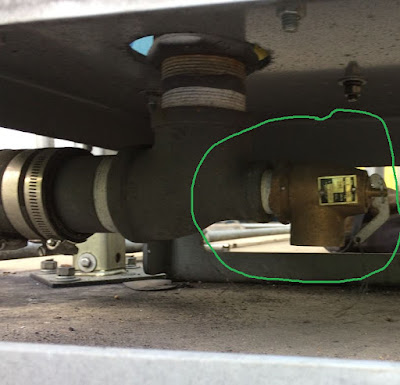

Thirdly, the pressure relief valve is easy to forget and completely ignored too, especially when it is hidden somewhere, and should be tested too. For example, the valve of the above PD blower (Figure 1&4) was beneath the frame.

|

| Figure 4 the Pressure relief valve beneath the frame |

In the final report, all the items that have been inspected are listed, so the customer knows what we did and our recommendations on the system.

Leak Test, Air Balancing, Trouble-shooting, and System Evaluation services by Airvate

- Dye test for bag/cartridge leak

- Dust collection system and industrial ventilation system Testing and Air Balancing

- Technical services: field survey and dust collection system audit / evaluation and trouble-shooting

- New system start-up

- Dust sample analysis

- Dust collector selection and sizing: baghouse, wet scrubber, cyclone, settling chamber, drop-out box, etc.

Comments

Post a Comment

Feel Free To Leave Your Comment Below!