Introduction

A

damper is a device that adjusts the volume of airflow passing through the

outlet, inlet or duct.

By

proper adjustment of all dampers in a system, a desired distribution of

airflows in all the branches can be obtained, while minimizing the total

airflow of the system to save energy— this is also termed air balancing.

The

most common dampers used in industrial ventilation and dust collection systems

to balance airflows are slide gate dampers (The slide gate, also called “blast

gate or cut-off” damper).

Interaction between a fan and dampers

As

the damper opens or closes to adjust the airflow in a system, fan operation

moves to a new point on the fan curve.

Dampers

increase the total resistance of a system; the fan airflow output decreases

while increasing the total static pressure produced by the fan. Fan efficiency

may also be affected if the fan was not selected with the additional resistance

by dampers in mind.

However,

if dampers are employed only to produce the desired distribution and the fan

speed is adjusted properly, the pressure requirement for the system will be

nearly always lower than without the dampers. This is also a partial reason why

air balancing can save energy cost.

When designing a ventilation or dust

collection system, the calculated amount of air leakage of the whole system

should be added to the selected fan capacity and so noted either in the

specifications or on the drawings. It should be done the same for the

additional resistance caused by dampers.

Many fan drives, or even the fans

themselves, have had to be changed because duct system air leakage or extra

resistance by dampers was ignored by the system designer.

Selecting

straight flat blast gate dampers as an example, Airvate calculated the

resistances for various ratios of insertion depth to duct diameter.

If you want to know the resistance by a

curved slide gate (Concave or Convex), you are encouraged to email Airvate

directly.

In

Table 1, a damper is used to increase the resistance of the branch but still

keep the same duct velocity to avoid settlement of dust, so a smaller diameter

of duct doesn’t have to be selected. Then, the pressure loss will be added to

the total pressure loss of that branch in the calculation for the whole system

design. The pressure losses under different insertion ratio and duct velocity

are tabulated.

|

| Table 1: Damper Resistance at Different Insertion Ratio and Duct Velocity |

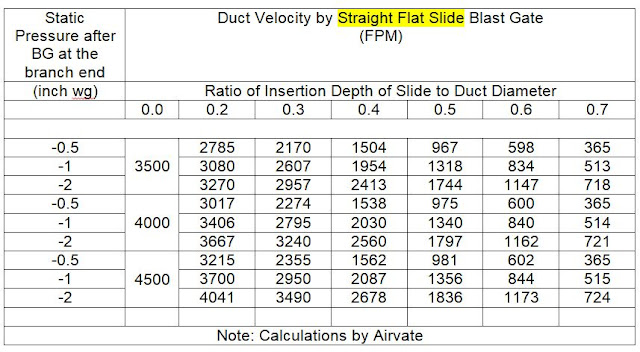

In

Table 2, when a damper is adjusted and the static pressure at the branch end

doesn’t change dramatically (this is normally true in a large ventilation

system) both the airflow rate and the duct velocity in the branch will be

reduced. This is the reason why dust settlement becomes a concern every time a

damper closes partially or fully.

|

| Table 2: Reduced Duct Velocity by Damper at Different Insertion Ratio |

Things to keep in mind when using dampers

There

are some issues associated with the use of dampers we have to pay attention to.

Many times when a dust generated point is turned off, users

simply cut off the branch by closing the blast gate completely, and believe

this will save energy and other branches can have more airflow. Actually, this

is strongly not recommended, since the amount of saving in heat and power is not great

enough to offset the disadvantages. Especially in the design stage, the suction

main must be designed for unduly high velocities to avoid dust settlement in

case that some gates are closed.

After

blast gates are put into use in a dust collection system, if the dust is

abrasive, the sharp edge of the damper will become smooth gradually, and this

can reduce the resistance of the damper at a given insertion depth.

The

damper resistance definitely will be affected, more or less, if there is any

accumulation of dust on the slide gate or just downstream or upstream of it.

Accumulation of dust on the downstream side would greatly reduce the

resistance. On the contrary, if the accumulation of dust is at the position beyond

the reach of the gate, this will increase the resistance of the branch (or

section).

- The friction between the slide and the damper should not be too high.

- Dampers are usually avoided when sticky materials are in the ducts.

- Damper slides should be inspected periodically and cleaned regularly as sticky or stringy dusts can be caught on the slide of the damper. Plugging might occur due to rags, pieces of paper and other material that are sucked into the duct by the fan. Flammable materials caught on a damper could create a fire hazard. Hence, care should be taken to avoid flammable materials.

- The location of the damper on a duct is also important for proper operation of the system. Whenever space is available on-site, a damper should never be located near elbows and other disturbances that may influence the pressure drop. Dampers can become sources for material build up if not located properly.

- Moreover, blast gates should be locked after the air balancing work is finished.

- If slides are lost or damaged, they should be replaced immediately, so the damper and the whole system can function properly as expected.

Industrial Ventilation and Dust Collection Services by Airvate that you can afford:

- Industrial Ventilation and Dust Collection systems testing and Air Balancing

- Whole system trouble-shooting

- Dye Testing for Bag Leak: Once a baghouse collector is installed or if there’s any hint that bag leak is possible in an existing baghouse, Airvate can do a Dye testing step by step.

- Technical Services: Field Survey / Dust Collection System Evaluation

- New System Start-up: Step by step, including system balancing, baghouse controller optimization, and fan belt tension adjustment, etc.

Comments

Post a Comment

Feel Free To Leave Your Comment Below!