This post includes 3 sections:

- One pressure gauge reading is high but the baghouse works fine

- One pressure gauge reading is high and indicates baghouse problem

- Explanation about 2 types of differential pressures

One pressure gauge reading is high but the baghouse works fine

When we

were doing an onsite project, the customer mentioned that one of their

baghouses had a higher differential pressure, which was around 10” H2O. It seemed

too high for a baghouse, but apparently it worked fine.

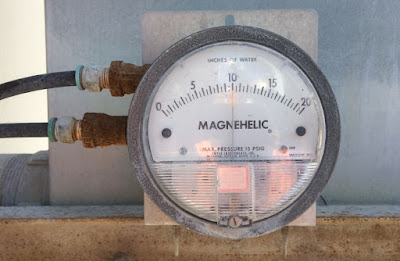

He led

us to the baghouse gauge (as shown in Figure 1). At first, we thought that the

differential pressure reading was between the clean-air plenum and dirty-air

plenum, so we told him it is an indication to replace the bags, since they

might all be dirty and clogged. However, after we accidently checked the hose

connection points, we found that the differential pressure reading is actually between

the baghouse’s inlet and outlet, and it

is a Flange-To-Flange differential pressure, for which a 10” reading is normal.

We explained this to him.

This

baghouse was manufactured by Dustex.

One pressure gauge reading is high and indicates baghouse problem

The customer wanted us to check the other baghouses’ gauge readings, and we did see a baghouse with a high reading, which was a little bit higher than 10” H2O, as shown in Figure 2.

This time we checked the hose connection points carefully, and the differential pressure reading above was between the clean-air plenum and dirty-air plenum, so this baghouse did need its bags replaced if the gauge still worked and the hoses were not jammed. We also suggested him to check the clean plenum before replacing bags too.

It took

us only a couple of minutes to clear the customer’s confusion about

differential pressures, and we offered remedies to the problematic baghouses. He

was thankful for our advice.

Explanation about 2 types of differential pressures

Normally,

all baghouses are equipped with a differential pressure gauge, but what they

measure is different.

A

baghouse’s differential pressure is a key parameter indicating how well your

baghouse is operating.

Differential

pressure is measured between,

1.

Clean

plenum and dirty plenum (mainly including pressure drop caused by bag itself,

bag outlet with or without a venturi), and

2.

Baghouse

inlet and outlet, flange to flange (mainly including pressure drop caused by

baghouse inlet, bag itself, bag outlet, baghouse outlet) ,

as illustrated in Figure 3.

The Flange-To-Flange differential pressure is always bigger than that between Clean Plenum and Dirty Plenum.

Comments

Post a Comment

Feel Free To Leave Your Comment Below!